The new EX / ATEX-certified cable harness measures more than 46 meters, weighs over 1 tonne and ends on each side with the extremely durable connectors of the TENEO TEX series.

The mighty TENEO power cable harness will serve for the safe transmission of high voltage between the terrestrial electrical switchboard and the top of the drilling rig. In a potentially explosive atmosphere, the 690 V distribution is ensured not only by the durable braiding of the cabling, but also by the spark-proof connectors of the TENEO TEX series, which in all respects exceed the requirements of ATEX certification.

The harness consists of three separate electrical phases and one ground conductor. For a trouble-free placement in the construction of the drilling set, we designed a 46-meter-long bundle: the initial 8 meters of the cable harness are branched into three separate conductors for easy connection to the switchboard, the last meter then forms the end for connecting appliances at the top of the tower. For the final segment, we tailor-made massive stainless steel handles that simply fit into the existing load-bearing structure.

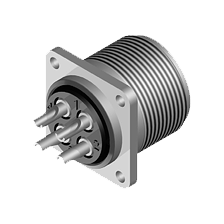

Because it is an installation in a hazardous environment in the mining industry, we have connected TENEO TEX single-pin connectors to both ends of the cable harness. They can transmit up to 990 A / 1,000 V and thus exceed customer requirements by almost 40%. Their spark-resistant construction and fully hermetically sealed connection to the conductor make the TENEO TEX series an ideal solution for gaseous atmospheres with a risk of explosion and for installations with the need for compatibility with established Amphenol or Winchester products.

This cable harness is further proof of our ability to efficiently produce tailor-made solutions that are not only quickly available to the customer, but also cost-effective.

You can see photos from the cable harness assembly in the gallery. A time-lapse video from the final stage of packing and preparing the expedition is below.