We effectively use the technology of pressing and thermoforming of thermosets for the production of rugged plastic insulating parts of TENEO circular connectors.

TENEO circular connectors are not only the result of machining. We use a number of modern and time-proven technologies to manufacture individual connector components.

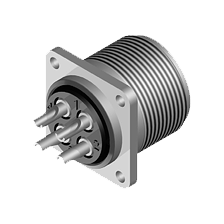

One example is the production of insulators for VS / VSG / VST connectors. We manufacture the insulators of the VS line connectors using the method of plastic pressing and thermoforming. A suitable loose granulate is heated and pressed into a mold to create a solid mechanically and temperature-resistant connector insulator in a precise shape requiring minimal post-production retouching. The insulator thus fits precisely into the metal body of the VS connector and thus ensures maximum resistance and tightness when used in hermetic installations.

Unshielded multi-pole VS connectors are designed for use in control, automation and telecommunications technology, stationery and mobile devices, signaling and remote control applications, as well as in heavy industry. A threaded coupling nuts with the possibility of sealing is used for the connection. The design of the connector allows connecting and disconnecting the circuit under voltage (but not under current load), and this with all poles of the connector simultaneously. For example VS series connectors are used for connecting flight instruments in Czech and Polish aircraft & drones, both military and civil. They are popular for their robustness and increased climate resistance.