Blog

News and articles in one place.

We have produced 1.5km long cable harnesses for an oil mining rig in Uzbekistan

As a result of gradual degradation in the inhospitable environment of the oil industry and frequent handling, irreparable damage occurs to each cable harness. Therefore, a customer from Tashkent approached us with a request for the production of cable harnesses that can be placed in an already operating mining system. It will go through a total overhaul process and the new TENEO cable harnesses will significantly extend its life. The entire solution was custom made from scratch. After obtaining the basic needs of the customer and clarifying the input technical parameters, we prepared a complete project including a combination of suitable wires, steel handles and connectors.

Because the bundles connect the most distant devices at the top of the tower (Top Drive), extreme lengths of cabling were required. It has a length exceeding 1.5 kilometres, of which 580 meters are only for the power cable harness. The length is also reflected in the weight attacking 1.6 tons in the case of a powerful power cable harness. The weight of TENEO drilling rig cable harnesses is not only determined by their length, but also demonstrates the robustness of the design.

TENEO harnesses and EX connectors resist not only aggressive oil industy chemicals, but also withstand harsh mechanical handling. For example, the harnesses must withstand being run over by heavy trucks and cargo vehicles while maintaining their spark-proof features and resistance to electromagnetic interference. We implemented antistatic shielding using 900 meters of special braid manually wound on the cable.

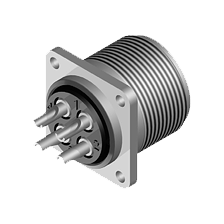

We finished the cables with a combination of industrial connectors of the TENEO TEX - TENEO TSL series for the control cable harnesses and TENEO TEX - TENEO TNR series in the case of the power harness. Thanks to the use of ATEX/iECEX certified TEX connectors, both types of TENEO cable harnesses are fully spark-proof, exceeding the requirements of international standards and compatible with established Amphenol and Winchester standards. The power cable harness can safely transmit currents of up to 1 000 A. The control harness consists of 4 cables that contain up to 50 individual wires.

To attach both types of harnesses to the construction of the mining set, we designed and made special flanges from stainless steel. The customer simply places these 50 kg giant handles into the current structure of the oil tower and thus secures the bundles in place. With no need for any modifications.

The entire solution for a customer from Uzbekistan belongs to our custom-made projects. We sucesfully aim to solve any interconnection need in countless industrial fields.

AMPER 2023 is coming! Please accept our invitation

After a year, we are again pleased to invite all our current and new business friends to visit the AMPER fair, of which we are a traditional part. We will be pleased not only by your visit to the exhibition itself, but also by a pleasant sitting together over a glass of something good in the backstage.

This year, the entire team behind the TENEO brand is enriched by a new colleague, Ing. Michal Řehoř, who took over the portfolio of connectors and charging stations. If you haven't met yet, please consider this as a great opportunity to get to know each other and share up-to-date information.

This time you will find our distinctive stand in corporate red-white-black colors in the northwestern part of hall F, in the second aisle, at exhibition position 2.05. Please, look at a detailed map in the gallery of this article.

If you do not yet have access to the fair, please accept free tickets from us. You will receive them on your e-mail address after completing this form. Please enter: 20543-108 as the verification code.

One-ton cable harness for explosive environment

The mighty TENEO power cable harness will serve for the safe transmission of high voltage between the terrestrial electrical switchboard and the top of the drilling rig. In a potentially explosive atmosphere, the 690 V distribution is ensured not only by the durable braiding of the cabling, but also by the spark-proof connectors of the TENEO TEX series, which in all respects exceed the requirements of ATEX certification.

The harness consists of three separate electrical phases and one ground conductor. For a trouble-free placement in the construction of the drilling set, we designed a 46-meter-long bundle: the initial 8 meters of the cable harness are branched into three separate conductors for easy connection to the switchboard, the last meter then forms the end for connecting appliances at the top of the tower. For the final segment, we tailor-made massive stainless steel handles that simply fit into the existing load-bearing structure.

Because it is an installation in a hazardous environment in the mining industry, we have connected TENEO TEX single-pin connectors to both ends of the cable harness. They can transmit up to 990 A / 1,000 V and thus exceed customer requirements by almost 40%. Their spark-resistant construction and fully hermetically sealed connection to the conductor make the TENEO TEX series an ideal solution for gaseous atmospheres with a risk of explosion and for installations with the need for compatibility with established Amphenol or Winchester products.

This cable harness is further proof of our ability to efficiently produce tailor-made solutions that are not only quickly available to the customer, but also cost-effective.

You can see photos from the cable harness assembly in the gallery. A time-lapse video from the final stage of packing and preparing the expedition is below.

Visit us at the Amper 2022 trade fair!

We would like to invite you to the Brno Exhibition Center, where you will find our unmissable black and red exhibition stand in Hall F (at position 2.07). We will be happy to guide you through all our product and technological innovations and hand over newly created catalogs and leaflets. We will also be happy to share your current needs and your plans for the future, with which we can be helpful. So come take a look, meet us or just talk with us without obligation.

If you are interested in getting one-time tickets, please contact us.

New cable harness for Bentec 350 drilling rig

Custom made cable harness TENEO TEX AUX newly provides Power supply of auxiliary equipment of the drilling set of the company MND Drilling & Services a.s.. Due to its location in the epicenter of an explosive gas atmosphere, our solution exceeds the requirements of ATEX certification and thus conducts energy in each of the 19 conductors safely and in all conditions.

This is mainly due to the use of TENEO TEX series connectors. We have fine-tuned their construction for the specific needs of the mining industry. However, not only the connector itself is spark-proof. We also solve fully hermetically the connection of the connector to the cable. Long time developed TENEO potting compound uncompromisingly seals the joint and withstands extreme environmental conditions.

In addition, we have designed special stainless steel handles for this 225 kg giant. With this customization, we ensured a trouble-free attachment of the TENEO cable harness to the already existing Bentec hinges without the need for additional costs for the modification of the supporting structure.

We are pleased to be able to customers such as MND Drilling & Services a.s. provide comprehensive tailor-made solutions - everything from design and project, through construction, own production, assembly to international guarantees.

You can see how we finalized the EP cable harness in the video below.

Close

CONNECTOR LINE

FINDER

TEXShow details

TSLShow details

MOGShow details

TNRShow details

BSShow details

VSShow details

SRShow details

RMShow details

RWNShow details

ZGTShow details

Close